Core Structure of High Speed Cartoning Machines

Machine Frame and Structural Design for Durability and Precision

Every high speed cartoning machine starts with a solid welded steel frame designed to stand up against vibrations when running fast. These machines often use reinforced stainless steel alloys which keep things aligned within about 0.2mm accuracy while cranking out over 300 cartons per minute. The whole build needs to be rigid enough so it doesn't start resonating from all that motion, something that would mess up the filling process. This matters a lot in pharma work where the FDA wants tolerances better than 0.1%. That's why manufacturers include special vibration dampening components plus leveling systems right at ground level. These features help keep everything running smoothly even if the factory floor isn't perfectly flat.

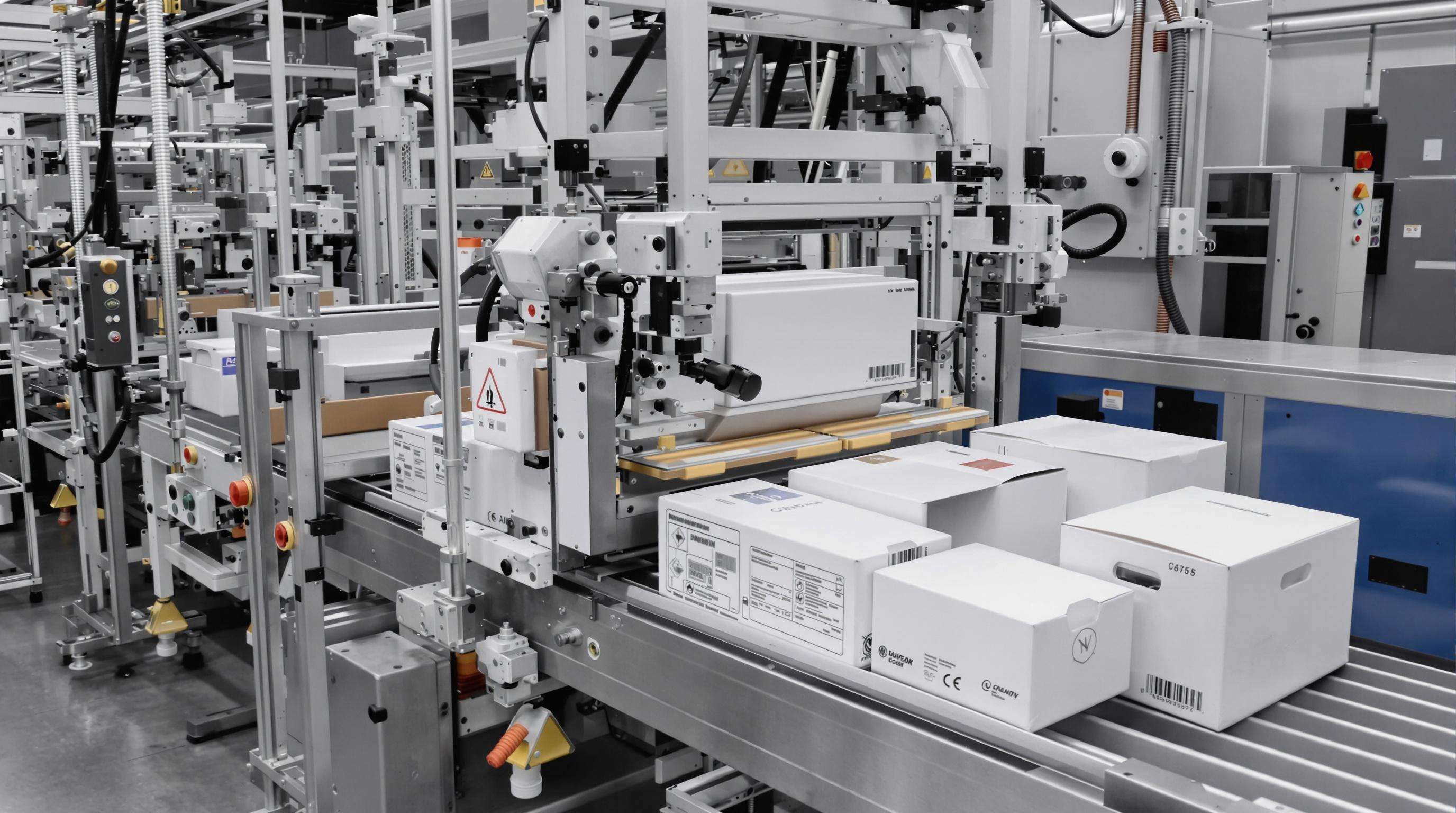

Key Components and Their Integration in High Speed Cartoning Machine Systems

The system runs on four main parts working together: product feed conveyors, those fancy Cartesian robots, the folding units, and gates that reject faulty items. All these components talk to each other through programmable logic controllers, or PLCs as they're called in the industry, which keeps everything moving smoothly without any hiccups. For movement control, we rely on precision servo motors that handle all the delicate positioning tasks. And there's something else too - rotary encoders check where things are located roughly every 40 milliseconds to make sure nothing goes off track. What makes this setup really flexible is its modular design. When production needs change, operators can switch between different packaging formats pretty quickly. We've seen setups go from handling toothpaste tubes to blister packs within about 90 minutes, sometimes even faster depending on how prepared the team is beforehand.

Carton Magazine and Storage Mechanism for Uninterrupted Operation

The vertical cartridge style magazines keep feeding flat blanks one after another thanks to those spring loaded platforms working together with hydraulic lifts underneath. When the stacks start getting lower, the automatic height adjustment kicks in so everything keeps moving smoothly at around 450 pieces per minute. We've got vacuum assisted separators making sure nothing gets fed twice, while those photoelectric sensors let operators know when stock is running low before it actually runs out completely. For certain applications, manufacturers offer models equipped with climate controlled chambers inside that help stop cardboard from warping due to excess moisture exposure over time.

Suction Cup Assembly for Reliable Carton Blank Extraction

Silicone suction cups extract blanks using Bernoulli-effect vacuum generators producing 25kPa negative pressure. Multi-cup arrays automatically adjust to carton dimensions via pneumatically controlled positioners. Anti-strip lips prevent edge peeling, while self-cleaning nozzles resist adhesive buildup. This assembly achieves over 99.94% extraction reliability across 50 million cycles under ASTM testing protocols.

How High Speed Cartoning Machines Work: Operation and Process Flow

High speed cartoning machines integrate mechanical, pneumatic, and automated control systems to deliver precision at industrial scale. The process unfolds in four synchronized phases: blank extraction, carton erection, product loading, and sealing, ensuring rapid, reliable packaging for pharmaceuticals, food, and consumer goods.

Working Principle and Step-by-Step Operational Process

It all starts when those vacuum suction cups grab hold of flat carton blanks coming out of the magazine and then shape them into three dimensional forms. Before anything else happens, sensors check if the cartons are intact. Products come in through an infeed conveyor that's timed really precisely, almost down to the millisecond mark. According to industry data from last year's Packaging Machinery Efficiency Report, top companies can actually run this whole operation at around 600 cartons per minute while maintaining nearly perfect accuracy rates of about 99.5%. Pretty impressive stuff for automated packaging systems these days.

Feeding and Conveyor System Synchronization for Seamless Product Flow

Timing belts and servo-driven conveyors align incoming products with carton positions. In blister pack systems, sequential loading delays product entry by 0.2-second intervals to prevent jams. This synchronization reduces waste by 23% compared to manual packaging methods.

Pusher Unit Mechanics and Precision in Product Insertion

Angled pusher arms with rubberized grips insert products within 0.5 mm positional tolerance. Pneumatic actuators apply 15-20 N of force, ensuring consistent placement without damaging fragile items such as glass vials or cosmetic compacts.

Folding and Closing Mechanisms for Secure Carton Sealing

After insertion, rotary tuckers fold flaps at 120° angles, and hot-melt adhesive guns apply 0.1 g of glue per seal point. Pressure plates compress the flaps for 0.8 seconds optimized for strong bond formation across temperatures ranging from 40°F to 100°F.

Automation, Control Systems, and Industry 4.0 Integration

Control panel and human-machine interface for real-time monitoring

Modern cartoning machines feature intuitive touchscreen interfaces displaying live data such as camera vision diagnostics, motor performance, and jam detection alerts. These dashboards support immediate operator adjustments, enabling predictive interventions that minimize downtime and maintain over 95% target efficiency during line synchronization.

Role of PLCs and sensors in ensuring consistent performance

Programmable Logic Controllers (PLCs) coordinate motors, actuators, and sensors to sustain high-speed operations. Photoelectric sensors detect carton positions with ±0.5mm accuracy, while vibration feedback loops dynamically adjust conveyor speeds to maintain alignment during insertion cycles. This closed-loop control prevents misfeeds at speeds exceeding 200 cartons/minute.

Integration with packaging lines and Industry 4.0: IoT and data analytics

Cartoning machines equipped with IoT technology send information about things like how many cartridges they're using, temperature readings inside the machine, and how well the motors are running to central MES systems. These data points let maintenance teams know when parts might fail before they actually do, which cuts down unexpected shutdowns by around 40% for most production lines that have this setup. The Industry 4.0 connections aren't just for monitoring though. They allow factories to adjust carton sizes based on real time demand changes throughout their workflow processes. Some manufacturers claim they've seen roughly 25% improvements in production speed after implementing these data driven switching methods between different carton formats.

Performance Metrics: Speed, Efficiency, and Reliability

Throughput Rates and Uptime Benchmarks in Industrial Applications

Modern high speed cartoning machines achieve over 300 cartons per minute in pharmaceutical settings, with industrial standards requiring ≧98% uptime for continuous production. Hardened steel frames and servo-driven mechanisms help sustain these rates while minimizing wear.

| Metric | Industry Standard | Optimization Strategy |

|---|---|---|

| Speed | 200-400 cpm* | Multi-axis servo synchronization |

| Efficiency | 92-97% OEE** | Collision-free product path design |

| Reliability | <0.5% downtime | Self-lubricating guide rails |

| *cpm = cartons per minute | **OEE = Overall Equipment Effectiveness |

Balancing Speed and Reliability in High Speed Cartoning Machine Operations

Operating above 400 cpm often compromises carton integrity or alignment. Advanced models counter this with vision-guided insertion, which reduces misloads by 85% compared to mechanical guides, and adaptive torque control in pusher units for delicate items. A 2023 Packaging Digest study found these features maintained 99.4% seal integrity at 320 cpm.

Minimizing Downtime Through Predictive Maintenance and Robust Design

Predictive analytics prevent 73% of unplanned stoppages (Packaging World 2024) by monitoring motor current fluctuations within ±5% tolerance and flagging vacuum cup degradation at 80% efficiency loss. Modular components can be swapped in under 15 minutes, with one confectionery plant reporting a 41% reduction in monthly maintenance hours after retrofitting.

Industrial Applications and Future Trends of High Speed Cartoning

Pharmaceutical, food, and cosmetics: Key industries using high speed cartoning machines

Cartoning machines that operate at high speeds play a vital role across several industries including pharmaceuticals, food packaging, and cosmetics manufacturing. When it comes to pharmaceutical applications, these machines manage everything from blister packs to various types of bottles and vials, processing literally hundreds of product batches each day according to research published back in 2021 by Brown. For snack foods and ready meal producers, automated cartoners really make a difference. They can increase production output by around 60 percent compared to manual methods, plus they help cut down on those annoying damages that happen when products get jostled during transport. Cosmetic companies benefit too since their delicate items like perfume flacons and skincare jars require careful handling. The ability to customize carton designs means brands can create eye-catching packages that stand out right there on store shelves next to competitors' offerings.

Case Study: Cartoning automation in a global beverage manufacturer

One major drinks company got rid of those annoying production slowdowns when they brought together fast cartoning machines with vertical cartoners and conveyor belts that worked in sync. Their new setup managed an impressive rate of 450 packs every minute while cutting down on hands-on work by almost 60%. Changeovers between different product runs became much quicker too. The whole line was equipped with smart sensors that caught any problems with product feed right away, which kept operations running smoothly at around 99.4% efficiency even during busy holiday seasons. What really stood out was how versatile the system proved to be handling everything from single cans to six-packs without needing any tool changes, something that made scaling up production much easier for them.

Future trends: Scalability, automation, and smart packaging lines

The latest generation of cartoning equipment focuses on being able to scale up or down easily while connecting better with internet of things technology. Manufacturing plants are now able to switch production lines to accommodate different carton dimensions in roughly 90 minutes flat, which really helps when bringing new products to market quickly. The inclusion of vibration monitoring and temperature sensing tech allows for predicting when maintenance will be needed before breakdowns happen, cutting down on those expensive unplanned stoppages. We're also seeing some interesting developments where packaging machinery incorporates blockchain features that track material sources throughout the supply chain, making it easier to meet recycling regulations. All these improvements mean cartoning machines aren't just boxes on the factory floor anymore but instead become key components in factories that adjust themselves automatically based on real time data.

Stat Sources: Packaging automation benchmarks (Nguyen 2019), Global Pharma Insights (Brown 2021)

Throughput comparison based on pre-automation baselines

FAQs

What is the speed of high speed cartoning machines?

High speed cartoning machines can achieve over 300 cartons per minute, with some setups capable of running at speeds of up to 600 cartons per minute while maintaining high accuracy.

What industries use high speed cartoning machines?

These machines are commonly used in the pharmaceutical, food, and cosmetics industries for packaging various products, including blister packs, bottles, vials, snack foods, ready meals, perfume flacons, and skincare jars.

How do high speed cartoning machines maintain precision?

They utilize programmable logic controllers (PLCs), precision servo motors, rotary encoders, and advanced sensors for high-speed synchronized operations, ensuring precise positioning and alignment of cartons.

What are the benefits of automation and Industry 4.0 integrations?

Automation and Industry 4.0 integrations enable real-time monitoring, predictive maintenance, and efficient data utilization, leading to reduced downtime, improved production speed, and enhanced adaptability to changing demands.