Understanding Alu-PVC-Alu Blister Packaging Machine Materials and Their Pharmaceutical Benefits

Material Composition in Alu-PVC-Alu Blister Packaging

Alu-PVC-Alu blister packs are made up of three main parts. There's a tough aluminum layer on the outside, then a middle layer of polyvinyl chloride (PVC) that creates the shape where the medication goes, and finally another thin aluminum layer inside that seals everything tight. What makes this combination work so well is how these layers complement each other. The PVC gives the pack transparency and allows it to be formed properly in manufacturing equipment. According to industry data from Colorcon in 2023, this setup actually improves machine compatibility by around 20 to 30 percent when compared to blisters made entirely of aluminum. And those outer aluminum layers? They're not just there for show. They create a strong barrier against both moisture and light, which matters a lot because many medications start breaking down when exposed to either element over time.

Comparison of Alu/PVC-Alu vs. Alu/Alu Performance for Drug Protection

| Property | Alu-PVC-Alu | Alu-Alu |

|---|---|---|

| Moisture Barrier | 0.01 g/m²/day | <0.005 g/m²/day |

| Light Protection | 99% UV blocking | 100% UV blocking |

| Cost Efficiency | $0.08/unit | $0.15/unit |

| Pharma Use Cases | Antibiotics, vitamins | Biologics, light-sensitive vaccines |

While Alu-Alu offers superior barrier performance, Alu-PVC-Alu reduces material costs by 47% (Ponemon 2023) and remains effective for most solid-dose drugs that do not require extreme environmental protection.

Superior Moisture and Light Barrier Properties for Sensitive Medications

Alu-PVC-Alu packaging features two aluminum layers that cut down on moisture getting inside by around 90% when compared to regular plastic blister packs. This makes these packages really good for medicines that absorb moisture easily, such as some types of antibiotics we commonly see in pharmacies. Studies done over several years show that products stored in this type of packaging last between six to twelve extra months even when exposed to humid conditions. What's also important is how the dark aluminum part stops almost all UV light from getting through. We're talking about blocking out 99% of those harmful rays that can break down sensitive medication components over time. This protection matters a lot because many drugs lose effectiveness if they get too much sunlight exposure during storage.

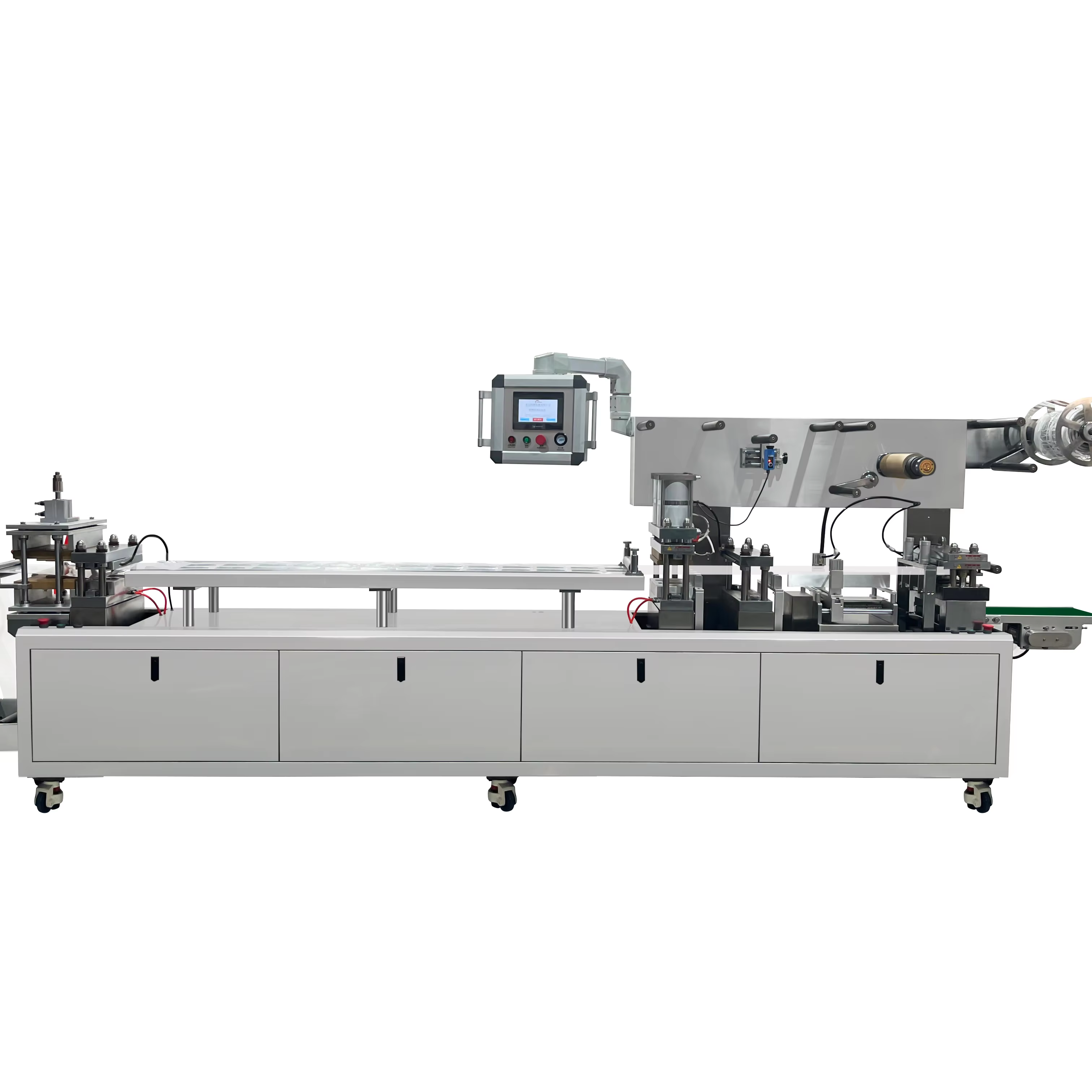

Blister Packaging Macine Design for Tablets and Capsules: Ensuring Safety and Patient Compliance

Unit-Dose Packaging and Its Impact on Medication Adherence

Blister packs for single doses really help people stick to their medication routines because each pill comes in its own labeled spot that shows if anyone has touched it before. These little packets cut down on mistakes when taking medicine by around 30 percent compared to just having pills in regular bottles, which matters a lot for folks who need to take multiple medicines at different times during the day. The latest numbers from Pharmaceutical Packaging Tech Report back in 2022 showed that more than seven out of ten oral medications worldwide come packaged this way nowadays. That makes sense since seeing exactly what's left helps track progress visually. And interestingly enough, studies found that individuals actually follow their doctors' instructions better by about 20 percentage points when everything is already sorted out and easy to read right there on the package.

Common Blister Configurations for Solid Dosage Forms

Blister packaging equipment comes in different setups depending on what kind of pills or capsules need packing. The push through type works best for those round little tablets we all know, whereas peelable blister packs tend to be better suited for bigger capsules or medications sensitive to moisture. Manufacturers have been adding child resistant mechanisms to their machines lately, which according to recent data from the Consumer Product Safety Commission cut down on kids accidentally swallowing medicine by about 40%. Another important feature is the embossed numbers and letters stamped right onto the blister cavities. This makes tracking products much easier and cuts down on mistakes when running these machines at full speed. Meeting international regulations becomes a lot simpler too with this kind of system in place.

Automation and Smart Technology in Advanced Blister Packaging Machines

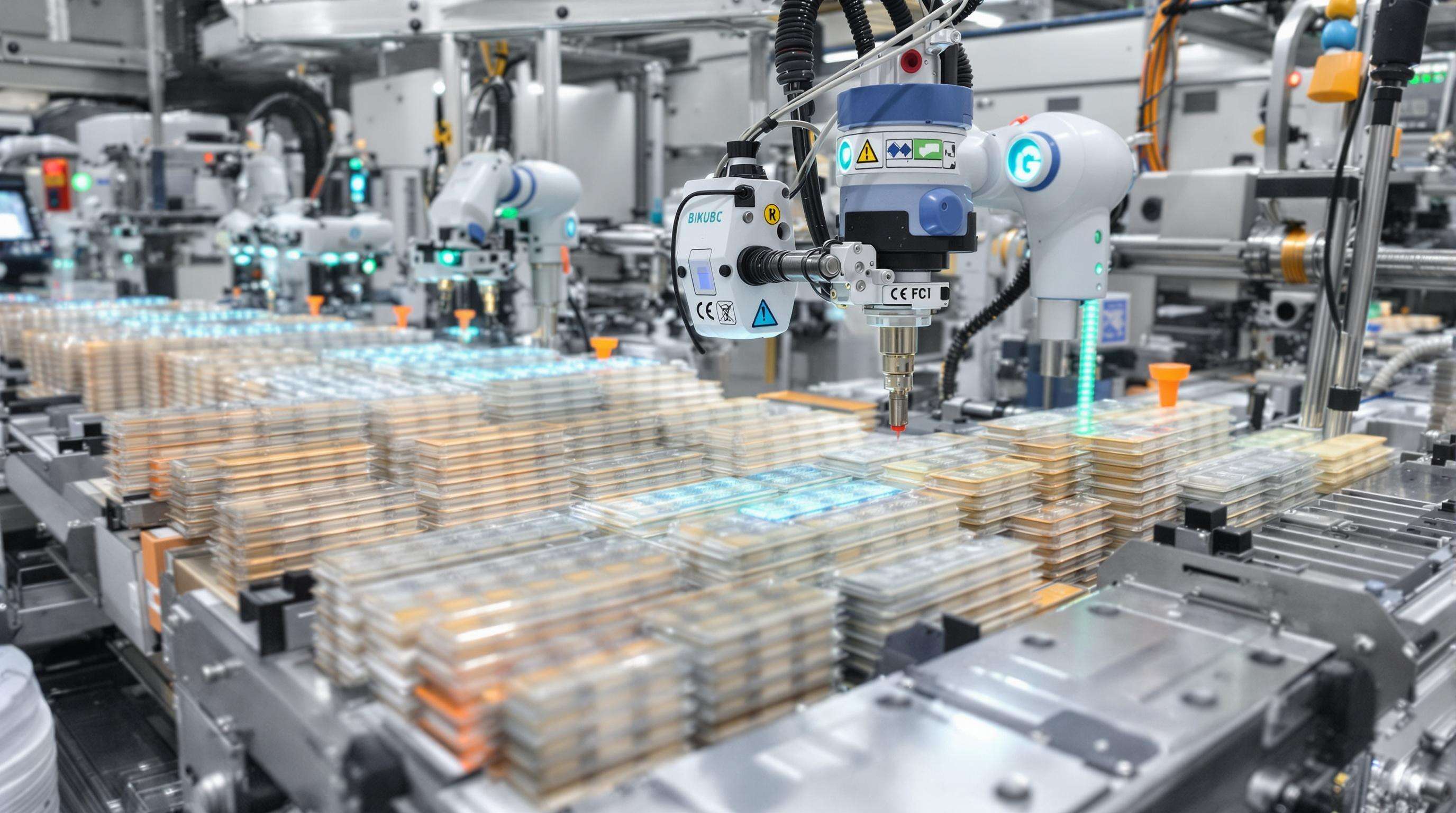

How Automation Enhances Efficiency in Blister Packaging Machines

Blister packaging machines that are automated can run anywhere from 40 to 60 percent quicker compared to manual setups because they handle materials, form cavities, and seal products much more efficiently. With robotics doing most of the work, human involvement drops around 90%, which means fewer chances for contamination and keeps production running at over 60 thousand units every hour. The vision systems built into these machines have really tight tolerances, about plus or minus 0.1 millimeter, so products get placed correctly almost every time. This cuts down on rejected items to under half a percent in facilities following good manufacturing practices. What's really impressive is how well everything connects together. These systems work hand in hand with the feeders that bring in raw materials and the inspection stations that check quality after packaging, resulting in equipment effectiveness ratings as high as 98% when running nonstop.

Integration of Smart Controls and Real-Time Monitoring Systems

The IoT sensors track more than fifteen different factors at once, like how hot the seals get between 175 and 200 degrees Celsius, plus the tension on the PVC film which should stay around 8 to 12 Newtons per meter. These cloud systems do some pretty smart stuff too, they can spot problems with seals before they actually happen sometimes even three days ahead of schedule. The machine learning stuff gets better when products change, say going from those little 6 mm round pills to bigger 18 mm capsule shapes. A recent study showed this cuts down on all the messing around during setups by about thirty percent. All this smart tech means machines keep running smoothly no matter what kind of products come through the line.

Balancing High Automation with Maintenance and Operational Complexity

Automated systems do cut down on labor expenses around $12.60 for each thousand packs produced, but there's a catch. These machines need regular upkeep that includes calibrating those servo motors roughly every 500 hours of operation plus replacing heat plates once a year. According to a study from PharmaTech back in 2022, plants that implemented augmented reality guided troubleshooting saw their downtime drop by almost half at 43%. The good news is that modular design approaches let companies grow their automation capabilities step by step. Most start with simple PLC controlled operations before moving on to more advanced AI powered inspection modules when they're ready.

Thermoforming and Sealing Technologies for Optimal Blister Integrity

Blister integrity is critical for medication safety and shelf life, relying on precise thermoforming and hermetic sealing. These processes must deliver consistent barrier performance without compromising production efficiency.

Thermoforming Process in Alu-PVC-Alu Blister Machine Operation

During thermoforming, rigid PVC film gets heated between around 110 to 150 degrees Celsius until it becomes soft enough to work with. At this point, the material is vacuum formed into exact tablet shapes using special alloy molds. These advanced A-ACP systems (which stands for Aluminum-PVC-Aluminum Cold Punching) keep the depth of these cavities really accurate, within plus or minus 0.1 millimeters actually. This level of precision cuts down on wasted materials by approximately 8 percent according to Pharmaceutical Processing reports. After forming, the parts are cooled quickly to set their shape properly before any drugs get loaded in them, which helps maintain consistent dimensions across all production runs.

Hot Sealing vs. Cold Forming: Applications and Performance Differences

The choice between hot sealing and cold forming depends on drug sensitivity and barrier needs:

| Parameter | Hot Sealing | Cold Forming |

|---|---|---|

| Temperature | 150–200°C applied to lidding | Ambient pressure forming |

| Barrier Efficacy | Moisture & gas blocking | Superior light/oxygen block |

| Material Compatibility | PVC, PVDC, multi-layer laminates | Aluminum-based composites |

| Optimal Use Cases | Standard tablets/capsules | Light-sensitive biologics |

Cold forming avoids thermal exposure, preserving heat-labile compounds, but requires specialized aluminum laminates.

Innovations in Sealing Integrity to Extend Shelf Life and Prevent Contamination

Cold punch systems today often feature tiny laser etched vents that let out trapped air when sealing happens, which stops those annoying bulges from forming. The ultrasonic method works differently it actually fuses materials at the molecular level without needing any glue or adhesive stuff. And guess what? This results in leak rates under 0.01%, which is pretty impressive if I do say so myself. Blister packs now come with built in oxygen scavengers too these little additives cut down on oxygen getting inside by around 97%. According to some recent research from Pharma Packaging Solutions back in 2024, this means vaccines stay good for an extra 18 months on the shelf. Manufacturers have also started adopting vacuum decay tests as their go to method for checking seals without damaging the package. Makes sense really since nobody wants compromised product quality because of bad packaging.

Regulatory Compliance and Future Trends in Pharmaceutical Blister Packaging

Meeting FDA and EU GMP Standards with Reliable Blister Packaging Machines

Modern blister packaging equipment now meets strict FDA 21 CFR Part 211 standards as well as EU Annex 1 guidelines for pharmaceutical production. Most manufacturers these days rely on machines that come with serialization features built right in, helping them stay compliant with both EU FMD and US DSCSA rules. The systems print those important unique device identifiers or UDIs along with expiration dates while running at impressive speeds sometimes over 400 blisters every single minute. And let's not forget about tamper evident seals either. According to research from Ponemon Institute back in 2023, better sealing tech has actually cut down on product recalls linked to packaging issues by around 34%. This makes sense when we think about protecting patients and staying within all those complicated regulations.

Emerging Trends: Sustainable Materials and Digital Integration in Blister Technology

Sustainable options are becoming more common across the industry right now. According to Yahoo Finance from last year, around 42% of manufacturers were already testing out things like bio based PVC materials or recycled aluminum back in 2024. Meanwhile, we're seeing smart machines come online that actually have IoT sensors built in for checking environmental conditions on the fly. Some companies are even using RFID tags along with blockchain technology to keep tabs on their supply chains. All these improvements point toward big growth ahead for the pharmaceutical blister packaging sector. GlobeNewswire reported recently that this market could grow at about 7.7 percent annually all the way through 2034. Companies are coming up with clever solutions too, like those special laser scored recyclable blisters. There's also AI powered vision systems now that can check not just how good the seals are but what kind of materials went into making them. This helps meet both green goals and strict regulations set by agencies like the EPA and REACH standards at the same time.

FAQ

What is Alu-PVC-Alu blister packaging?

Alu-PVC-Alu blister packaging consists of a multi-layer setup with aluminum on both the exterior and interior, sandwiching a PVC layer. This construction is meant to block light and moisture for pharmaceutical products.

How does Alu-PVC-Alu packaging compare to Alu-Alu?

While Alu-Alu offers superior moisture and light protection, Alu-PVC-Alu is more cost-efficient and sufficient for most pharmaceuticals, offering a good balance between protection and cost.

Why are blister packs beneficial for medication adherence?

Blister packs make it easier for patients to follow medication schedules as they provide visible cues, reducing errors by showing which doses have been consumed or are remaining.

What technological advancements are being integrated into blister packaging machines?

Machines now incorporate IoT sensors, automation for efficiency, and machine learning for adaptability, aiming to reduce downtime, enhance precision, and improve monitoring and maintenance practices.

Are there eco-friendly trends in blister packaging?

Yes, manufacturers are experimenting with bio-based and recyclable materials, as well as digital technologies, to meet sustainability goals while adhering to regulatory standards.

Table of Contents

- Understanding Alu-PVC-Alu Blister Packaging Machine Materials and Their Pharmaceutical Benefits

- Blister Packaging Macine Design for Tablets and Capsules: Ensuring Safety and Patient Compliance

- Automation and Smart Technology in Advanced Blister Packaging Machines

- Thermoforming and Sealing Technologies for Optimal Blister Integrity

- Regulatory Compliance and Future Trends in Pharmaceutical Blister Packaging

- FAQ