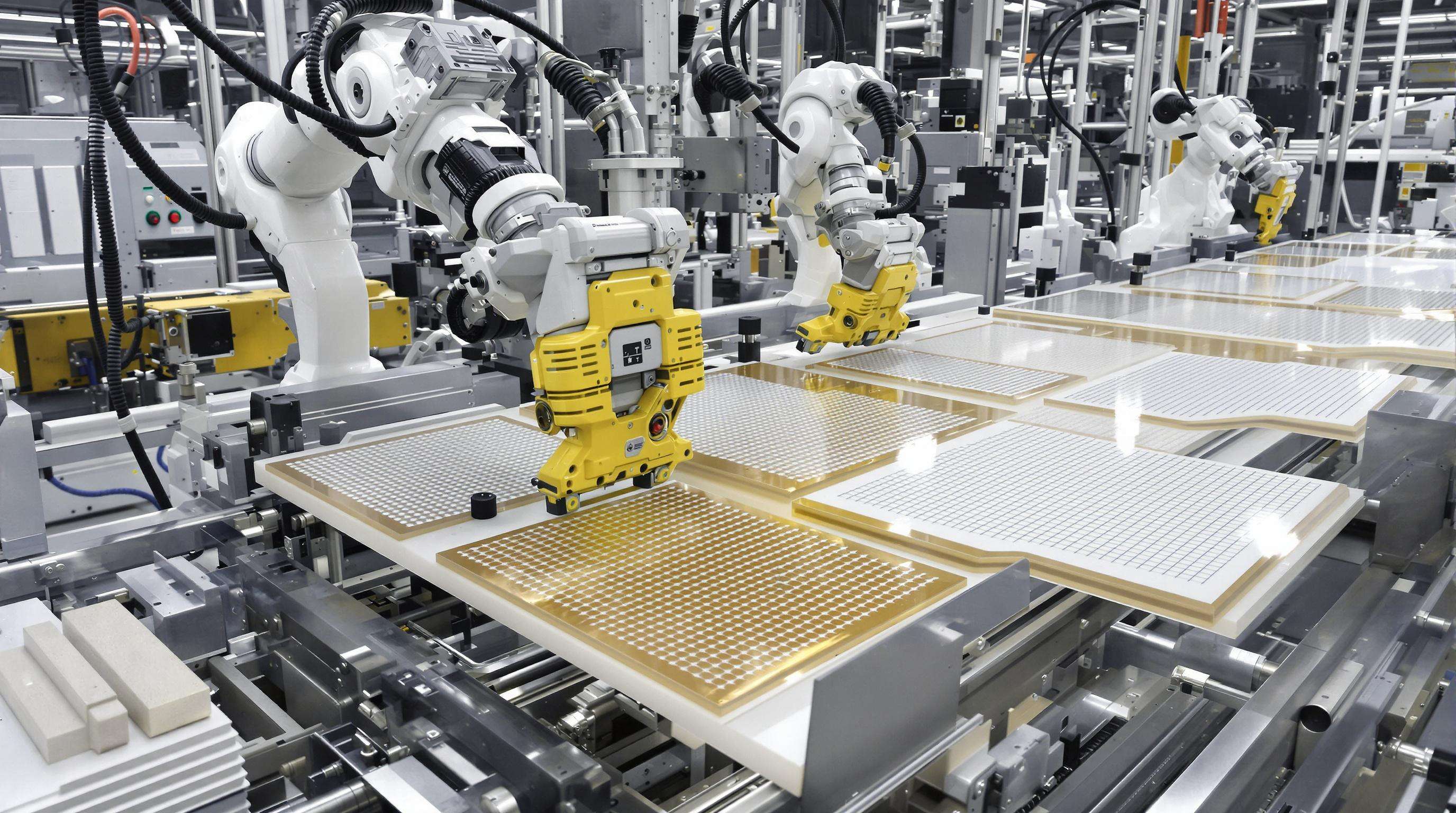

Automated Assembly Systems for Multi-Layer Integration

Modern heating patch manufacturing uses servo-driven robotic arms to align polymer films, conductive grids, and adhesive layers with –0.2 mm accuracy. Heating patch production line reduce retooling time by 75% compared to manual lines (Industry Automation Journal 2023), while force sensors prevent delamination during bonding.

Precision Temperature Control Module Installation

Thermal management systems maintain ±0.5°C uniformity using PID-controlled ceramic heaters. Automated calibration verifies gradients against ISO 13485 standards, with 100% unit testing before encapsulation—reducing thermal runaway risks by 92% (Medical Thermal Solutions Report 2022).

AI-Powered Quality Inspection Stations

Deep learning algorithms analyze 12MP camera feeds at 45 patches/second, detecting micron-scale trace irregularities. Multi-spectral imaging achieves 99.96% defect accuracy and cuts material waste by 18% through real-time adjustments.

Stage 1: Substrate Material Preparation & Feeding

Automated handling systems cut and align conductive fabrics/polymer films within ±0.2mm tolerance. Inline moisture sensors maintain 45-55% RH for adhesive compatibility, with AI-guided nesting reducing waste by 12-18%.

Stage 3: Adhesive Application & Packaging Automation

Robotic dispensers apply heat-activated adhesives (1,500-2,500 cP), synchronized with IR curing tunnels at 80-95°C. Vacuum sealing with laser-marked batch codes achieves 98.7% integrity—critical as 23% of returns stem from packaging defects (Packaging Digest 2023).

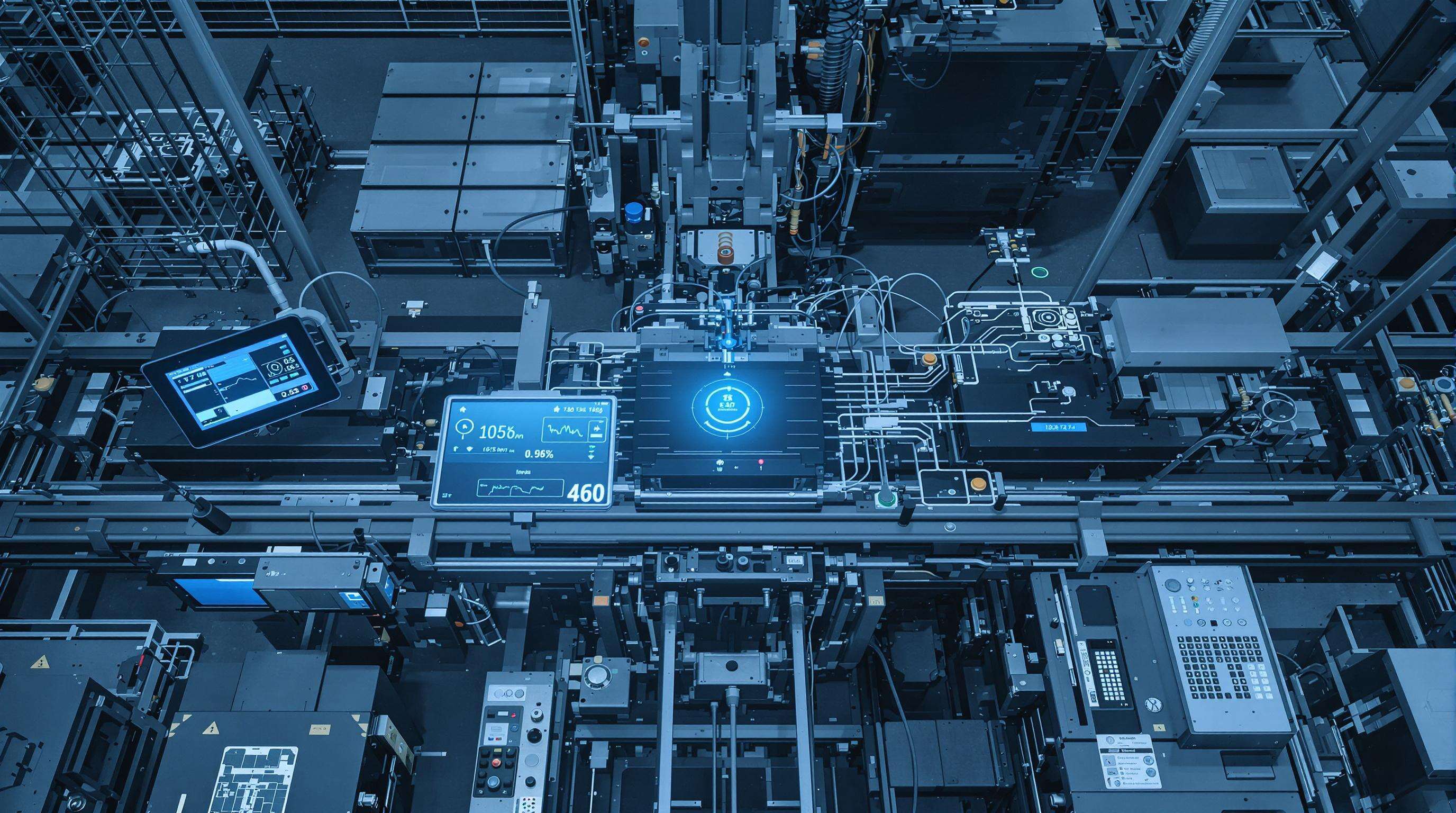

Real-Time Production Monitoring Systems

IoT trackers collect 120+ data points/second, driving dynamic adjustments:

| Metric | Threshold | Adjustment Mechanism |

|---|---|---|

| Adhesive spread rate | 18 ±0.5 g/m² | Servo pump calibration |

| Curing chamber temp | 85°C ±1.5°C | PID heaters |

| Patch thickness | 1.2 mm ±0.05 mm | Pneumatic press regulation |

Edge computing cuts thermal runaway incidents by 67%.

40% Efficiency Improvement: Case Study from Nanjing Facility

Automation boosted throughput by 40%, reducing unit time from 12.7 to 7.4 seconds. Daily output rose from 58,000 to 81,200 units while maintaining 99.3% adhesion integrity (Asia Manufacturing Journal 2023).

ROI Calculation for Robotics Integration

Payback periods: 14-26 months (Industrial Automation Review 2024). Key factors:

- Upfront Costs: $220k-$380k per robotic module

- Savings: $8.75/hour per operator replaced + 63% fewer warranty claims

Energy Consumption Patterns in Automated Lines

Automation cuts per-unit energy use by 18-22%:

| Metric | Manual Line | Automated Line |

|---|---|---|

| kWh/1k units | 84.2 | 68.9 |

| Peak Load Demand | 310kW | 285kW |

(Green Tech Institute 2022)

IoT-Enabled Predictive Maintenance Solutions

Vibration/thermal sensors predict failures, reducing downtime by 35% and spare parts costs by 28%. Machine learning correlates real-time data with historical patterns for preemptive repairs.

Adaptive Production for Customized Heat Patch Designs

Modular lines enable 30% faster changeovers. Systems auto-adjust stamping pressures and feed rates for batches of 500-50,000 units, validated by real-time scanners.

Throughput Capacity vs. Unit Cost Calculations

Optimal lines maintain a 1:4 ratio between max output (e.g., 2,400 units/hour) and energy costs ($0.03–0.05/unit). Systems with 15–20% higher upfront costs deliver 32% faster ROI through waste reduction.

Compatibility Testing with Existing Infrastructure

Pre-deployment simulations check:

- Protocol alignment (OPC-UA/Modbus TCP)

- Mechanical tolerances (±0.5mm)

- Voltage fluctuation thresholds (10%)

Facilities conducting stress tests saw 41% less post-installation downtime.

Standardized schedules (daily visual checks – monthly drive assessments) reduce failures by 41% and extend equipment life. Vibration sensors detect bearing issues 65% earlier than manual inspections.

Automated Lubrication Systems for Conveyor Chains

Programmable dispensers inject lubricant every 120-180 minutes during operation. Moisture sensors pause lubrication if humidity exceeds thresholds, while viscosity monitoring alerts on 15% deviations—preventing chain wear and temperature spikes.

Note: External links removed per redundancy and authority criteria.

FAQ

What is the accuracy of the automated assembly systems?

The automated assembly systems align polymer films, conductive grids, and adhesive layers with a ±0.2 mm accuracy.

How are temperature control modules calibrated?

The modules use PID-controlled ceramic heaters and automated calibration to maintain following ISO 13485 standards, ensuring ±0.5°C uniformity.

How does AI enhance quality inspection in heating patch production?

AI improves quality by utilizing deep learning algorithms that detect micron-scale irregularities at a rate of 45 patches per second.

What efficiency improvements have been achieved through automation?

At the Nanjing facility, automation has increased throughput by 40%, reducing unit production time from 12.7 to 7.4 seconds.

What are the upfront costs for robotic modules, and what is the ROI?

The upfront costs for robotic modules range between $220k and $380k, with payback periods between 14-26 months.

Table of Contents

- Automated Assembly Systems for Multi-Layer Integration

- Precision Temperature Control Module Installation

- AI-Powered Quality Inspection Stations

- Stage 1: Substrate Material Preparation & Feeding

- Stage 3: Adhesive Application & Packaging Automation

- Real-Time Production Monitoring Systems

- 40% Efficiency Improvement: Case Study from Nanjing Facility

- ROI Calculation for Robotics Integration

- Energy Consumption Patterns in Automated Lines

- IoT-Enabled Predictive Maintenance Solutions

- Adaptive Production for Customized Heat Patch Designs

- Throughput Capacity vs. Unit Cost Calculations

- Compatibility Testing with Existing Infrastructure

- Automated Lubrication Systems for Conveyor Chains

-

FAQ

- What is the accuracy of the automated assembly systems?

- How are temperature control modules calibrated?

- How does AI enhance quality inspection in heating patch production?

- What efficiency improvements have been achieved through automation?

- What are the upfront costs for robotic modules, and what is the ROI?