Core Functionality and Form-Fill-Seal Process of Blister Pack Equipment

What is a blister packaging equipment?

Blister packaging machines handle the whole process of making those little plastic pockets we see holding pills, candy, or small electronic gadgets. The system works through several stages including thermoforming where the plastic is shaped into individual compartments, then precise filling operations ensure each cavity gets exactly what it needs, followed by sealing processes that lock everything in place. What makes this packaging so effective? It creates a barrier against dampness, dirt getting in, and accidental breakage during transport. Looking at the parts involved, there are special molds called forming dies that create the actual blister shapes. Then comes the dosing mechanism which places products accurately inside each pocket. Finally, heated sealing plates press the blister sheet onto either metal foil or plastic covers, creating that secure seal we all recognize when opening packaged items.

Key technical features and advantages of blister packaging equipments

Modern blister pack equipment offers:

- Material versatility: Processes PVC, PET, aluminum, and cold-form foils

- Speed optimization: High-speed rotary models handle up to 1,200 blisters per minute

- Microprocessor controls: Maintain ±0.2°C temperature stability for consistent seals

- Integrated quality checks: Automatically reject defective packs using vision systems and weight sensors

These capabilities reduce material waste by 18–22% compared to manual methods while helping pharmaceutical manufacturers meet FDA and GMP compliance standards.

Overview of the form-fill-seal process in blister packaging

The form-fill-seal (FFS) workflow consists of four primary stages:

- Thermoforming: A polymer sheet is heated to 140–160°C and vacuum-formed into cavities

- Product loading: Tablets or components are placed precisely into blisters via robotic mechanisms

- Lid sealing: Aluminum foil or plastic film is bonded under 30–50 psi pressure at 150–180°C

- Punching: Individual blisters are cut with hydraulic precision at ±0.1mm accuracy

This fully automated process eliminates direct human contact with sensitive products and achieves defect rates below 0.1% in validated systems.

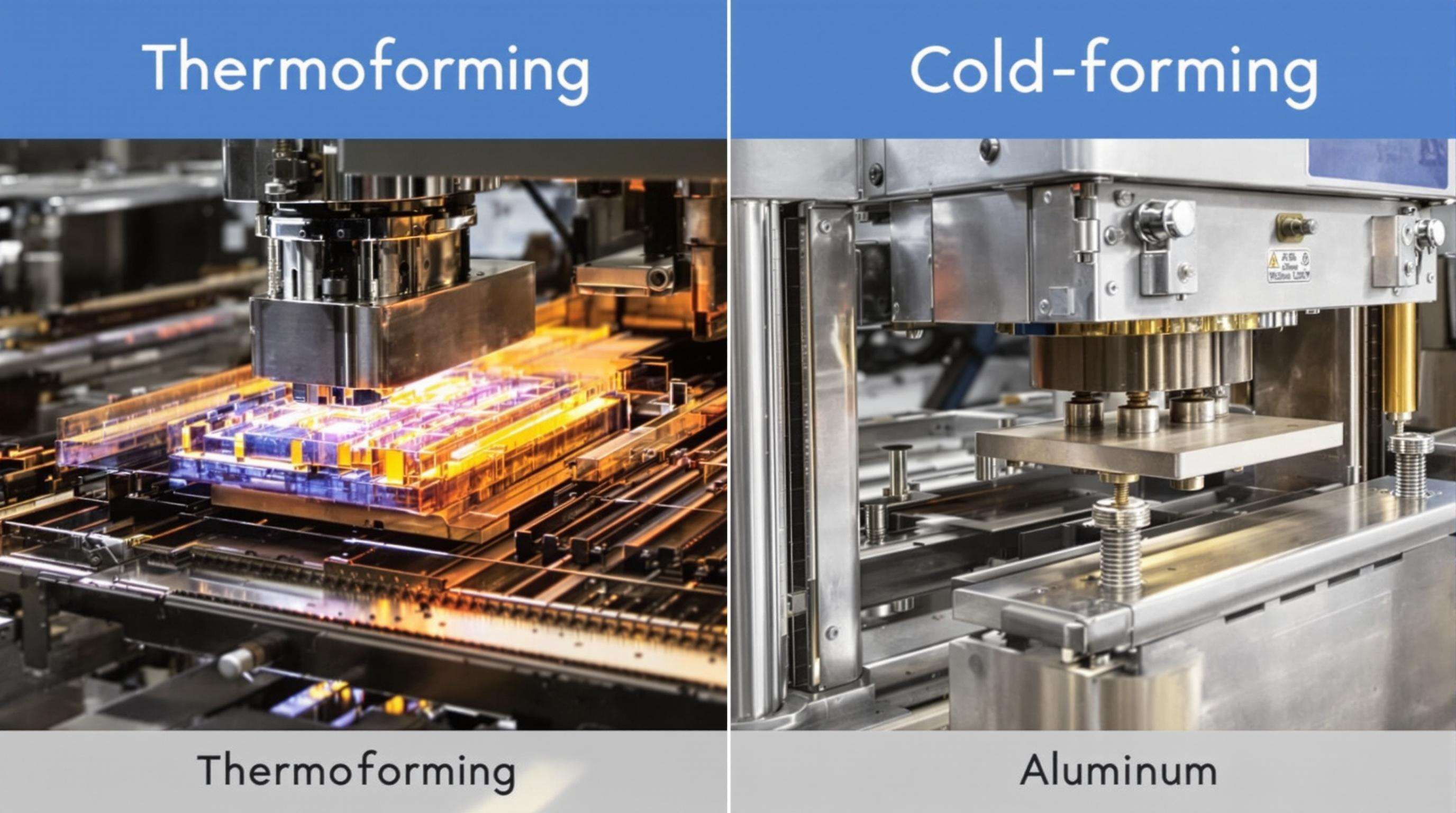

Thermoforming vs. Cold Forming: Mechanisms and Material Considerations

Heat-based thermoforming: blister pack working mechanism and temperature control

The process of thermoforming blister packaging starts when thermoplastic sheets are heated between around 140 and 180 degrees Celsius until they become soft enough to work with. This heating makes the plastic pliable so it can be molded into different shapes as needed. Getting the temperature just right is really important because it helps the material flow evenly throughout the mold without breaking down from getting too hot. Most manufacturers rely on thermocouple sensors to keep things stable within about plus or minus 2 degrees. These sensors help manage how long the plastic stays at each stage, preventing it from cooling too quickly while forming cavities. As a result, every batch comes out looking pretty much the same structurally, which matters a lot for quality control in production runs.

Forming methods: air pressure, plug assist, and depth specifications

Modern thermoforming setups typically combine positive air pressure with plug assist features to get the job done right. The air pressure starts forming the cavity shape, whereas those plug assists really come into play when making deeper parts. These can go well past 60mm depth while keeping walls pretty consistent across the piece. When manufacturers set their vacuum levels between about 0.6 to 0.8 bar and program how far the plug moves during forming, they end up with parts that are accurate to around plus or minus 0.3mm. That kind of precision matters a lot in pharmaceutical manufacturing where even small deviations can be problematic.

Cold forming process in blister packaging: precision and barrier benefits

Cold forming works by applying significant pressure, usually around 200 to 300 kilonewtons, to shape aluminum laminates while they're at room temperature. This creates those permanent cavities we need without any heat involved. For pharmaceutical applications, this is actually really important because it keeps those sensitive active ingredients safe from thermal damage. When we talk about what we get after processing, the aluminum lamination offers amazing protection against environmental factors. Tests show moisture transmission stays well below 0.01 grams per square meter per day, and oxygen gets through at less than 0.005 cubic centimeters per square meter daily. To put that into perspective, these numbers are roughly seven times better than what we typically see with standard PVC materials in similar applications.

Material compatibility and efficiency in cold-formed blisters

Cold-formed blisters rely exclusively on aluminum-PVC-PCTFE laminates to achieve required pharmaceutical barrier performance. These lines operate at 90% of maximum capacity, outperforming thermoforming systems, which average 75% utilization. With 30% fewer rejected packs and reduced need for nitrogen flushing or secondary packaging, cold forming offers higher overall efficiency despite elevated material costs.

Filling and Sealing Technologies in Blister Packaging Equipments

Precision dosing and filling technologies in blister pack equipment

Automated dosing systems in modern blister machines use vibratory feeders, rotating brushes, and alignment guides to ensure accurate placement of tablets or capsules. These systems achieve over 99.5% dosing accuracy, preventing underfills or overfills. Capable of handling 100–800 blisters per minute, they maintain strict hygiene standards essential for pharmaceutical production.

Heat seal vs. cold seal: durability, cost, and application differences

Most blister packaging operations go with heat sealing these days, which accounts for around three quarters of all production runs because it creates those solid, tamper-proof seals everyone wants. The process basically involves applying heat between 120 and 180 degrees Celsius along with pressure to stick materials such as aluminum or plastic onto the base of the blister pack. For products that can't handle the heat, there's cold sealing instead. This method uses special pressure sensitive adhesives that activate without any heating involved, so it works great for things like certain vitamins or supplements that might degrade under high temperatures. Of course, this convenience comes at a price point roughly 15 to 20 percent higher per unit compared to traditional methods. When deciding which approach to take, manufacturers typically opt for heat sealing when they need something really robust for pharmaceutical applications, while cold sealing becomes the choice when preserving delicate ingredients matters most.

| Parameter | Heat Seal | Cold Seal |

|---|---|---|

| Durability | High bond strength | Moderate strength |

| Cost | $0.02–0.05/unit | $0.03–0.07/unit |

| Applications | Tablets, capsules | Sensitive compounds |

Glue seal and other alternative sealing techniques

When situations require avoiding heat but still need good seals, glue sealing works at room temperature instead. Certain adhesives stick to delicate materials without causing any thermal damage. The field is seeing some interesting developments lately. Ultrasonic sealing creates heat locally via friction rather than applying direct heat everywhere. There are also new hybrid adhesives that actually consume oxygen as part of their function. These approaches help keep ingredients stable over time, something especially important for products that degrade easily. At the same time they form solid defenses against both moisture and oxygen getting in, which matters a lot for shelf life and product quality.

Automation and Modern Advancements in Blister Packaging Equipment

Integration of automation in blister packaging machinery

Modern blister packaging machines have become smart connected systems that transform how products are packaged. With robotic arms doing the delicate work, PLCs managing complex workflow stages, and industrial IoT sensors gathering live data throughout the entire production process. Most manufacturers these days install cloud dashboards on about two thirds of their new lines to keep tabs on performance metrics. The automation saves roughly 40% of what used to be hands-on labor, keeping things within really tight specs around plus or minus 0.3 millimeters over long production runs. Throughout the operation, various sensors monitor factors like film tension levels and sealing temps, making instant corrections when needed so quality stays consistent even if raw materials vary slightly from batch to batch.

Impact of intelligent functions on production efficiency

Smart tech such as predictive analytics and instant defect spotting really makes things run better. The machine learning stuff looks back at past performance numbers to figure out when maintenance should happen, which means factories can avoid those annoying surprise breakdowns that cost around 30% less downtime overall. For quality control, vision systems now check every cavity at an impressive speed of 400 frames each second. They catch flaws right away so no one has to waste time doing manual checks anymore. When it comes to sealing processes, modern systems automatically tweak pressure levels depending on how thick the film material is. This small adjustment actually boosts equipment effectiveness metrics by roughly 22%. And speaking of improvements, switching between different production runs takes less than 15 minutes nowadays, all while keeping production speeds well over 300 blister packs made per minute. These kinds of upgrades are changing how manufacturing works day by day.

Balancing high automation with maintenance complexity

Automation definitely boosts production rates, but comes with its own headaches when it comes to maintenance. Smart systems using predictive analytics can actually spot when parts are going to fail long before they do something nasty, sometimes as much as 200 hours ahead of time. This gives maintenance teams plenty of warning so they can schedule fixes during slower periods instead of emergency repairs at midnight. The modular approach makes life easier too. When a thermoforming station needs replacing, for instance, technicians can swap it out quickly without bringing the whole production line to a standstill. Regular training programs for technical staff cut down on mistakes that cause unplanned downtime by around half according to industry reports. And let's not forget about those backup systems either. Extra heating elements and other redundant components mean operations keep running even when something goes wrong somewhere else. For companies making millions of pills every day where stopping production means losing money fast, getting all these factors right becomes absolutely critical when choosing manufacturing equipment.

Types of Blister Packaging Equipment: Flat, Rotary, and System Selection

Comparison of flat station and rotary blister packaging machines

When it comes to blister packaging equipment, there are basically two main types on the market flat station (sometimes called shuttle) machines and rotary systems. Flat stations work with reciprocating molds moving in straight lines, which makes them pretty good for smaller production runs where output needs to stay around 80 blisters per minute or so. What really stands out about these machines is how easy they are to switch between different formats. A manufacturer changing product SKUs several times a week will find this feature extremely valuable. On the other side of things we have rotary machines that operate using a continuously spinning carousel mechanism. These bad boys can crank out over 600 blisters every minute thanks to their rotating design that cuts down on inertia problems. Plus they handle multiple tasks at once printing labels while applying lids for instance all while maintaining steady production rates. For companies running large scale operations in pharma or nutraceutical industries, rotary machines are often worth the bigger upfront cost even though they require significant capital investment initially.

Choosing the right blister pack equipment based on production needs

When picking equipment, it really matters how much we're making each day and what kind of products need to be produced. Compact flat machines work great when production runs stay below around 100 thousand units per day because they give manufacturers flexibility without breaking the bank. Rotary systems tend to perform better with materials that absorb moisture or react to oxygen exposure, like those tricky effervescent tablets that need constant nitrogen protection during processing. If the job calls for micro tablet arrays with tight tolerances of about plus or minus 0.1 millimeters, then servo driven rotary systems deliver much better results with fill variations typically staying under 0.3 percent compared to pneumatic shuttle models which can vary anywhere between plus or minus 5 percent. But let's not forget about maintenance expenses either. Rotary machines generally cost between forty to sixty percent more annually to maintain, which means doing proper ROI calculations becomes absolutely essential before committing to these systems for extended periods.

FAQ

What are the main types of blister packaging machines?

The primary types of blister packaging machines are flat station (shuttle) machines, which are ideal for smaller production runs, and rotary systems, best suited for large-scale operations due to their high-speed capabilities.

Why is blister packaging effective?

Blister packaging is effective because it creates a barrier against dampness, dirt, and accidental breakage during transport, thereby protecting the contents.

How do thermoforming and cold forming differ in blister packaging?

Thermoforming involves heating thermoplastic sheets to form cavities, while cold forming uses pressure to shape aluminum laminates at room temperature, offering superior barrier protection.

What factors should be considered when choosing blister pack equipment?

Consider production volumes, material properties, specific product requirements, and maintenance costs when selecting appropriate blister packaging machinery.

Table of Contents

- Core Functionality and Form-Fill-Seal Process of Blister Pack Equipment

- Thermoforming vs. Cold Forming: Mechanisms and Material Considerations

- Filling and Sealing Technologies in Blister Packaging Equipments

- Automation and Modern Advancements in Blister Packaging Equipment

- Types of Blister Packaging Equipment: Flat, Rotary, and System Selection

- FAQ