Heating Patch Manufacturing: End-to-End Workflow Overview

Understanding the Full Lifecycle of a Heating Patch

Making heating patches starts with picking out the right stuff - iron powder is key, along with activated carbon and some special polymers that hold everything together. Once these ingredients are gathered, they go through several steps including mixing them just right, controlling how much they oxidize, and getting their temperature settings spot on within the production line. Today's factories can actually make a whole batch from start to finish in around 6 to 8 hours now, which beats the old method that took nearly three days straight. The factory keeps an eye on things constantly during production, so most batches come out consistent at about 99.8%. This level of quality control means these products meet those tough ISO 13485:2022 requirements for medical devices, something manufacturers really need to stay competitive in today's market.

Key Stages from Raw Material Input to Final Packaging

- Material Preparation: Raw ingredients are precisely measured and undergo vacuum dehydration to eliminate moisture that could interfere with exothermic reactions

- Coating & Assembly: Multi-layer coating systems apply heat-retention films with ±0.2mm tolerance, ensuring uniform thermal performance

- Quality Gates: Each patch passes through three optical inspection stations before packaging to detect dimensional or structural defects

- Sealing: Pouches flushed with nitrogen extend shelf life to 36 months without preservatives by preventing premature oxidation

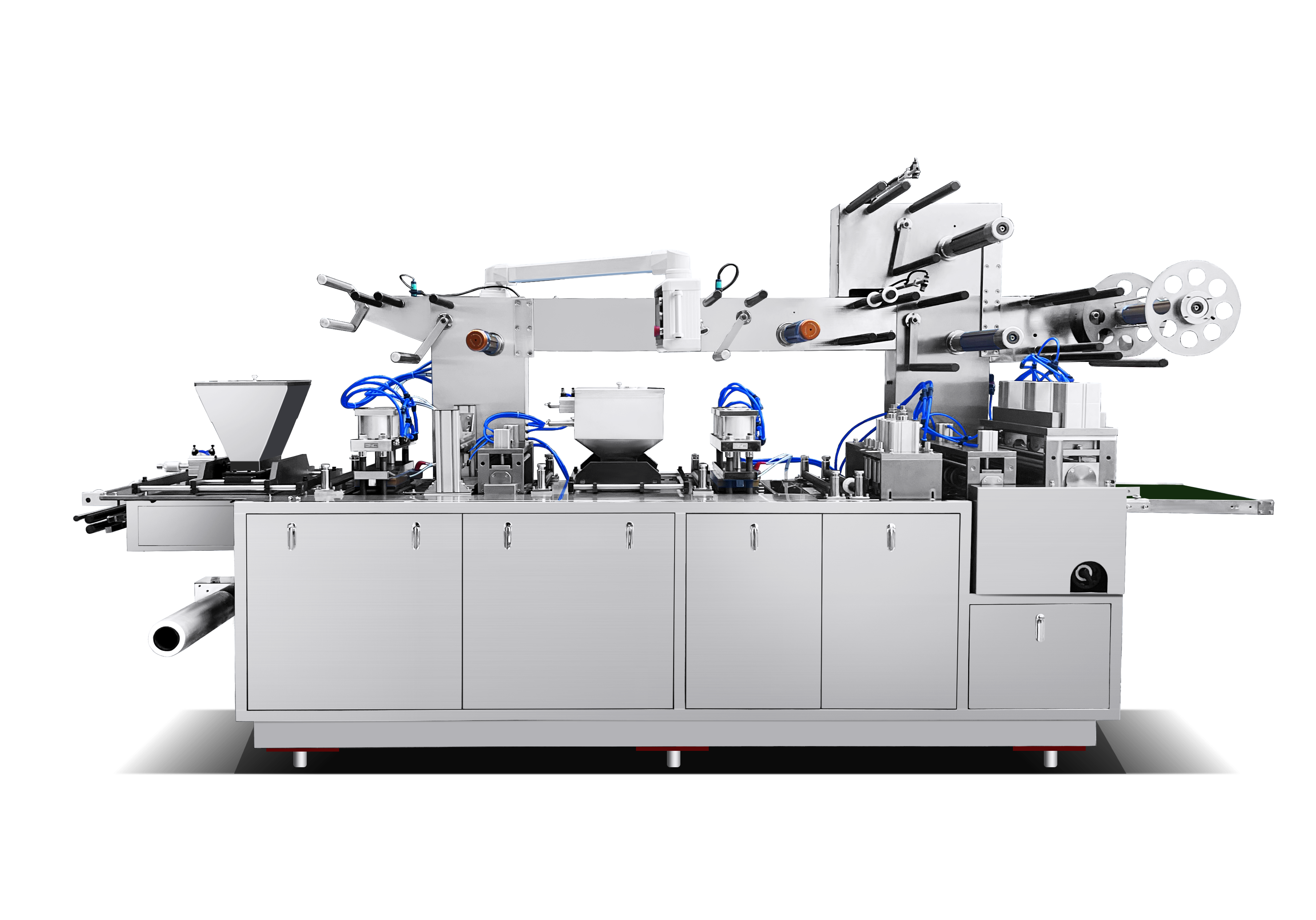

Role of Automation in Modern Heating Patch Production Lines

Automation drives efficiency and safety, with integrated robotics handling 87% of material transfer tasks and reducing human contact by 94% compared to semi-automated setups. Closed-loop control systems continuously monitor viscosity and adjust coating thickness in real time, minimizing waste to less than 0.5%—a dramatic improvement over the 8–12% typical in manual operations.

Core Technologies in Heating Patch Production Machinery

Advanced Coating Systems for Consistent Heat Distribution

Robotic coating systems with multiple layers apply conductive materials such as carbon-based inks within controlled environments where temperatures stay stable around plus or minus 1 degree Celsius. Maintaining this kind of environment is really important if we want consistent heat output from the finished product. The machines actually have these special sensors built into them that monitor viscosity continuously, keeping the coating thickness somewhere between 0.2 and 0.5 millimeters. This helps meet those strict FDA standards for thermal profiles that manufacturers must follow. When everything works properly, the result is about 95% consistency in thermal performance from one batch to another. Industry tests back this up, according to findings published by the Ponemon Institute last year. Such precision matters a lot when quality control is so crucial for end users.

Precision Cutting and Shaping Units for Uniform Patch Design

Laser-guided die-cutting technology has resolved longstanding issues with inconsistent patch edges. Today's equipment delivers ±50 micron accuracy, enabling complex designs while adhering to ISO 13485 medical device tolerances. The improvements over traditional methods are substantial:

| Parameter | Traditional Methods | Modern Laser Systems | Improvement |

|---|---|---|---|

| Cutting Speed | 200 patches/hr | 850 patches/hr | 325% faster |

| Material Waste | 12% | 3.2% | 73% reduction |

| Edge Consistency | ±500 microns | ±50 microns | 10x precision |

Integration of IoT and Real-Time Monitoring in Equipment

Smart production line machines typically come with around 18 to 22 IoT sensors monitoring different factors including hydraulic pressure ranging from zero to three hundred psi, plus heater cartridge temps between thirty and seventy degrees Celsius. A recent report from JAMA Medical Technology in 2023 showed that when companies use these sensor readings for predictive maintenance, they cut down on unexpected equipment failures by about thirty eight percent. Most factories now rely on cloud dashboards for real time production stats. These tools let workers tweak processes quickly enough to keep operations running smoothly with minimal interruptions, usually maintaining something close to 99.9% uptime across most facilities.

Case Study: Zhejiang Haoyuan Machinery's Smart Production Line

Zhejiang Haoyuan Machinery exemplifies the impact of full automation integration. Their AI-powered vision systems inspect 1.2 million thermal cells daily, detecting micron-level coating flaws with 99.7% accuracy. After implementation, adhesive failure rates dropped by 67%, and product changeovers accelerated by 41%, setting new benchmarks for efficiency and reliability in heating patch manufacturing.

Quality Control in Heating Patch Manufacturing: Safety, Performance, and Compliance

Standardized Testing Protocols for Thermal Output and Adhesion

The manufacturing process includes rigorous checks to confirm product performance meets standards. When it comes to thermal testing, companies run their products through special chambers that mimic actual usage environments. According to ASTM F2894-21 guidelines, these tests need to show temperature consistency within plus or minus 2 degrees Celsius across all surfaces. Regarding how well things stick, manufacturers perform those classic 180 degree peel tests. These tests check if patches can hold onto skin with at least 1.5 Newtons per square centimeter of force even after being subjected to harsh conditions for three days straight (think 40 degrees Celsius and 75% humidity). This ensures patients won't experience any issues with their medical devices coming loose while they're wearing them.

In-Line Inspection Systems for Defect Detection

Modern machine vision systems can inspect parts from all angles at around 120 frames every second, spotting issues like tiny air bubbles, adhesive that's not lined up properly, or areas where carbon fiber isn't distributed evenly across surfaces. The difference between these automated systems and what humans can catch manually is pretty dramatic too, cutting down on missed defects by roughly 40%. When it comes to sorting out what kind of flaw we're looking at, the AI behind these systems has been tested extensively and manages to categorize problems into about 12 different types while making mistakes less than 0.1% of the time during testing phases. This level of accuracy makes production lines safer overall and helps maintain consistent quality standards across batches.

Compliance with International Medical Device Regulations

The big players in manufacturing stick to ISO 13485:2016 when it comes to managing quality control, plus they follow FDA regulations under 21 CFR Part 807 for those product submissions before hitting the market. When talking about safety requirements, most companies need to stay within certain boundaries set by REACH regarding SVHC substances, which means keeping concentrations below that 0.1% weight by weight threshold. And for devices that run on electricity? They must pass tests according to IEC 60601-1 standards. Things have gotten even trickier lately with new EU Medical Device Regulation changes requiring complete lists of all materials used throughout production. As a result, many firms are now turning toward blockchain technology as part of their supply chains to track everything from raw materials through final assembly. This helps them maintain visibility across operations while staying ahead of potential compliance issues down the road.

Innovative Packaging Solutions for Heating Patch Shelf Life and Market Readiness

Moisture-Resistant Sealing Techniques for Extended Shelf Life

Vacuum-sealed aluminized layers combined with integrated desiccants preserve patch efficacy for over 36 months. A 2023 thermal therapy study found these formats retained 98% of active ingredients under 75% humidity, compared to 82% in standard packaging, significantly extending usable shelf life.

Child-Safe and Elderly-Friendly Packaging Designs

Press-and-rotate closures balance child resistance with accessibility for users with arthritis, requiring 12–15 lbs of downward force to open. Opaque blister packs featuring braille labels meet both safety and inclusivity standards, supporting broader patient access.

Sustainable Materials in Heating Patch Packaging Trends

Industry leaders now use plant-based cellulose films that biodegrade 90% faster than conventional plastics while maintaining equivalent moisture barriers. According to the 2024 Packaging Innovation Report, incorporating post-industrial recycled PET layers reduces carbon footprint by 41%.

Automated Counting and Blister Packing Efficiency

High-speed rotary fillers achieve 250–300 patches per minute with fewer than 0.2% counting errors, thanks to integrated vision verification. Robotic cartoning units with torque-controlled sensors cut material waste by 18% compared to manual packing, improving efficiency and sustainability across the final production stage.

FAQ

What are the main materials used in heating patches?

The primary materials used in heating patches include iron powder, activated carbon, and specific polymers that help in binding the ingredients together.

How does automation enhance heating patch production?

Automation significantly boosts production efficiency and safety. Integrated robotics perform material transfer tasks that reduce human contact by up to 94%, while closed-loop systems manage viscosity and coating thickness, minimizing waste dramatically.

How do modern machines ensure consistent cutting and shaping?

Modern machines use laser-guided die-cutting technology, which achieves ±50 micron accuracy, ensuring precise patch edges that adhere to stringent medical device standards.

What makes packaging designs child-safe and elderly-friendly?

Packaging designs incorporate press-and-rotate closures with braille labels, balancing child resistance with accessibility, requiring 12–15 lbs of downward force to open, making them ideal for elderly patients.

Table of Contents

- Heating Patch Manufacturing: End-to-End Workflow Overview

- Core Technologies in Heating Patch Production Machinery

- Quality Control in Heating Patch Manufacturing: Safety, Performance, and Compliance

- Standardized Testing Protocols for Thermal Output and Adhesion

- In-Line Inspection Systems for Defect Detection

- Compliance with International Medical Device Regulations

- Innovative Packaging Solutions for Heating Patch Shelf Life and Market Readiness

- FAQ